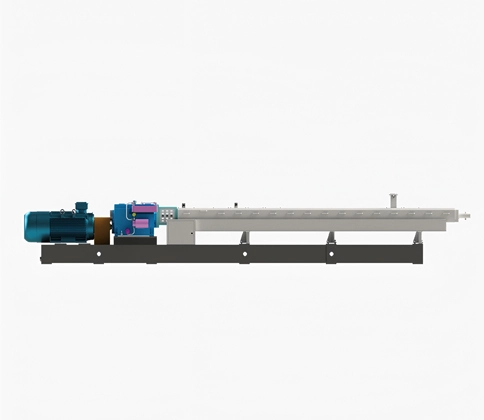

The rotor and the stator are precisely matched, and the optimized combination makes the system reach the best state. The working head (manufactured by rotor and stator forgings) has a claw structure with bidirectional material absorption and high shear efficiency, which forms a comprehensive kinetic energy, such as high frequency and strong circumferential tangent velocity and angular velocity through the rotor's smooth rotation at high speed. Under the action of the stator, strong and reciprocating hydraulic shearing, friction, centrifugal extrusion, liquid flow collision, and other comprehensive effects are formed in the reasonably narrow gap between the stator and the rotor. The above working process is repeated in the container, and finally, the product is obtained.

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский português

português Deutsch

Deutsch