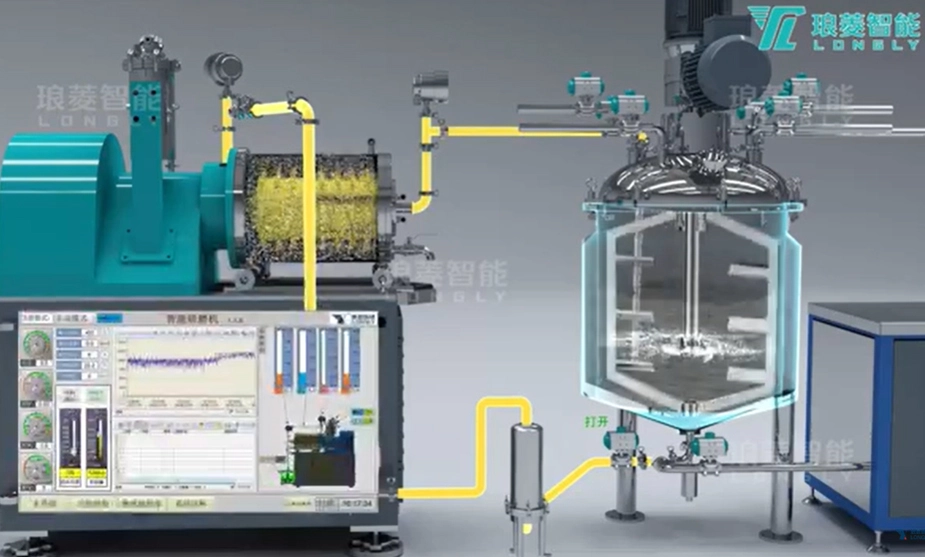

Dry grinding refers to the moisture content of the material not exceeding 4% during grinding. Wet grinding refers to grinding raw materials that are suspended in the carrier liquid stream, with the appropriate additives like dispersion addition to help grinding.

The moisture content of the material in wet grinding exceeding 50% can overcome the problem of dust flying.

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский português

português Deutsch

Deutsch

-1(1).webp)