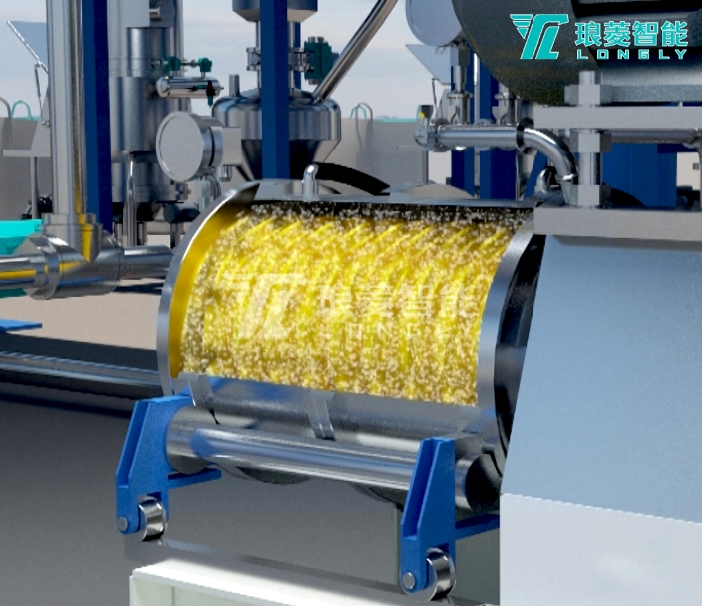

Mixing provides various inseparable and uniform mixtures, such as emulsions, suspensions, etc. Mixing multiple raw substances can obtain different materials with various properties, which is important in basic material processing in the chemical industry.

Deaerating is to remove dissolved gases like oxygen from liquids. Mixing refers to combining different substances into uniform mixtures.

In the field of raw materials in the chemical industry, mixing mainly means stirring solid with solid or liquid. Mixing can combine with the deaerating for uniformity and purity of mixtures.

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский