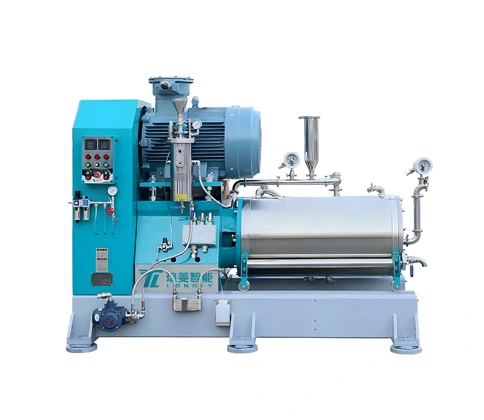

Micron bead mills include pin-type bead mills, disc-type bead mills, and basket-type bead mills.

Micron bead mill, an efficient grinding equipment, is mainly used to grind solid particulate materials to the micron level. Based on the high-speed movement and collision between grinding media (such as zirconium beads, and glass beads) and materials in a closed grinding chamber, it achieves ultra-fine grinding.

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский português

português Deutsch

Deutsch

-1(1).webp)