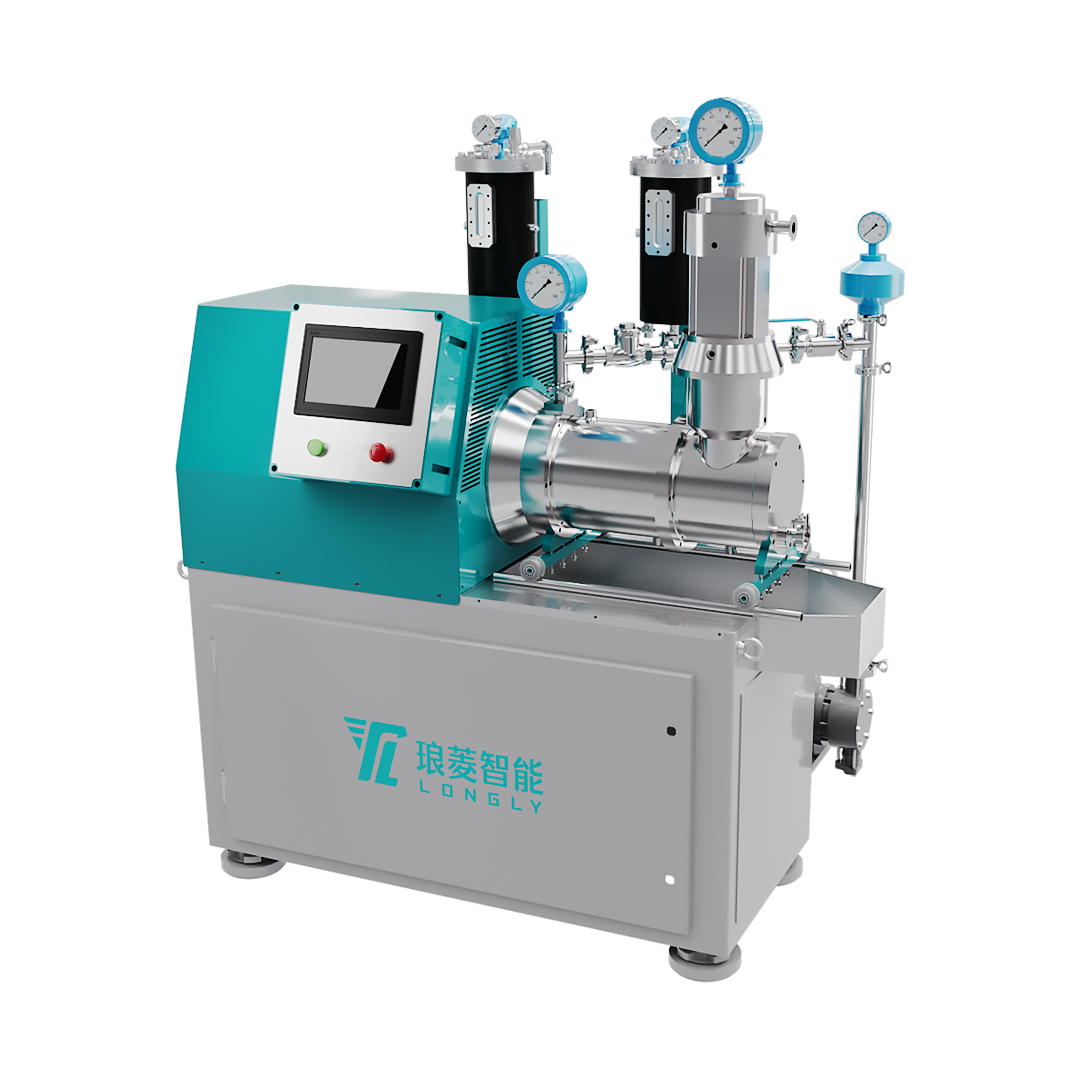

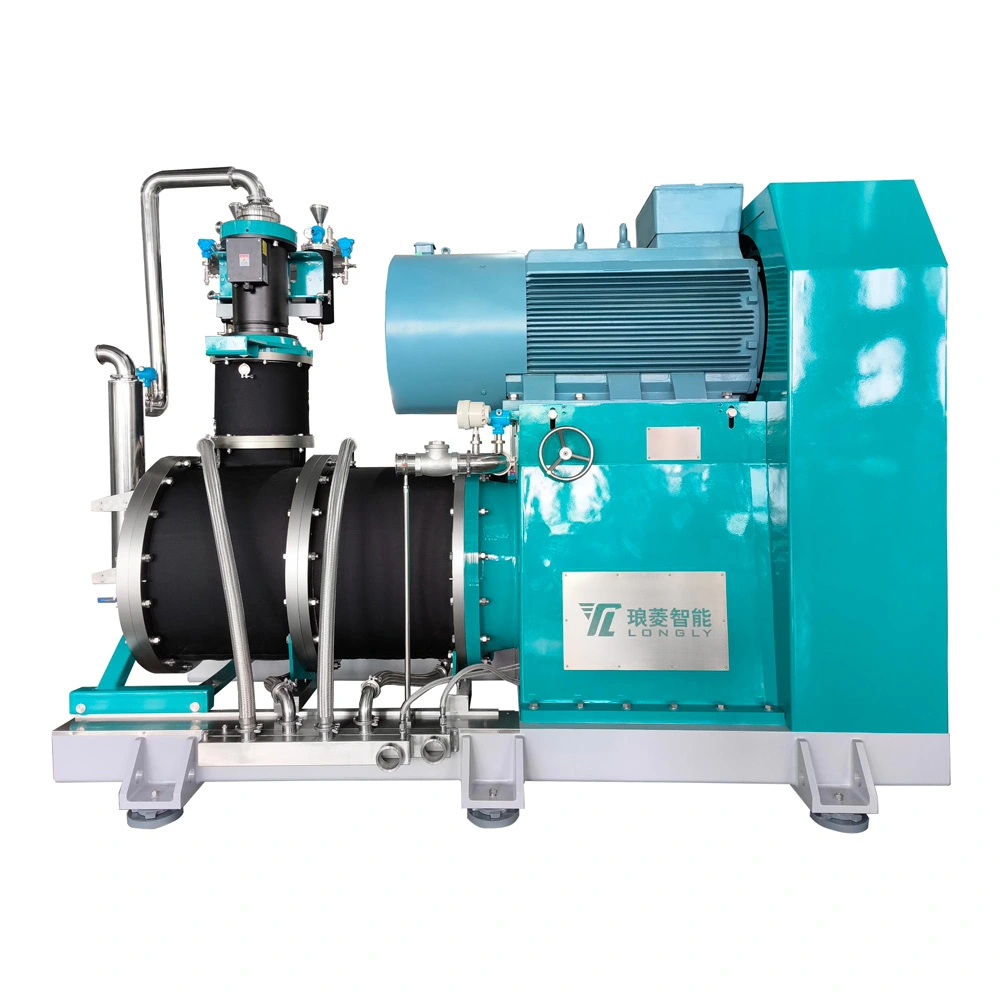

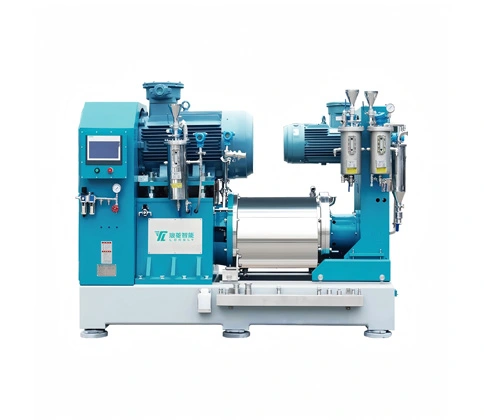

The vertical and horizontal bead mill NT-VE, developed with LONGLY's great efforts, will inject more flexibility and precision into wet grinding and bring good grinding performance. This unique innovation provides extraordinary grinding to the industry, demonstrating cutting-edge technology and grinding.

Nano Bead Mill NT-VE combines horizontal grinding and vertical centrifugal discharging, ensuring high efficiency and high quality in grinding, and has the advantages of bead separation in vertical. The slurries are pumped into the grinding chamber, pressurized, and rotated at high speeds in the gap between the grinding beads to perform functions such as dispersion and grinding. The milled materials are pressure-fed from bottom to top and discharged from above.

The pin-type rotor gathers high energy in the entire grinding area to achieve sufficient grinding, even with a small capacity. Centrifugal separator enables large flow processing and high-speed cycle operation.

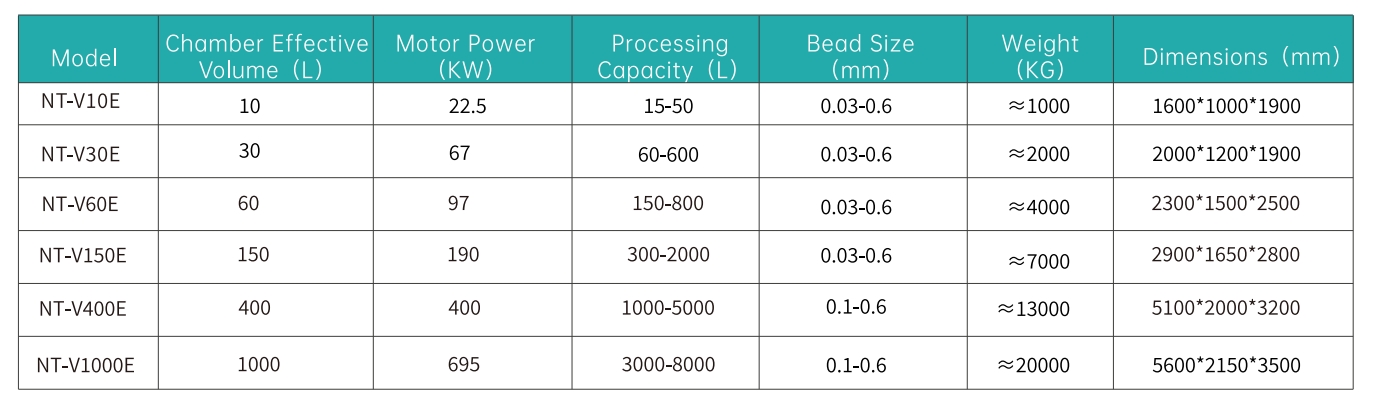

Different customized models are available from 10L to 1000L to meet customers' requirements from laboratory to large-scale production.

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский português

português Deutsch

Deutsch