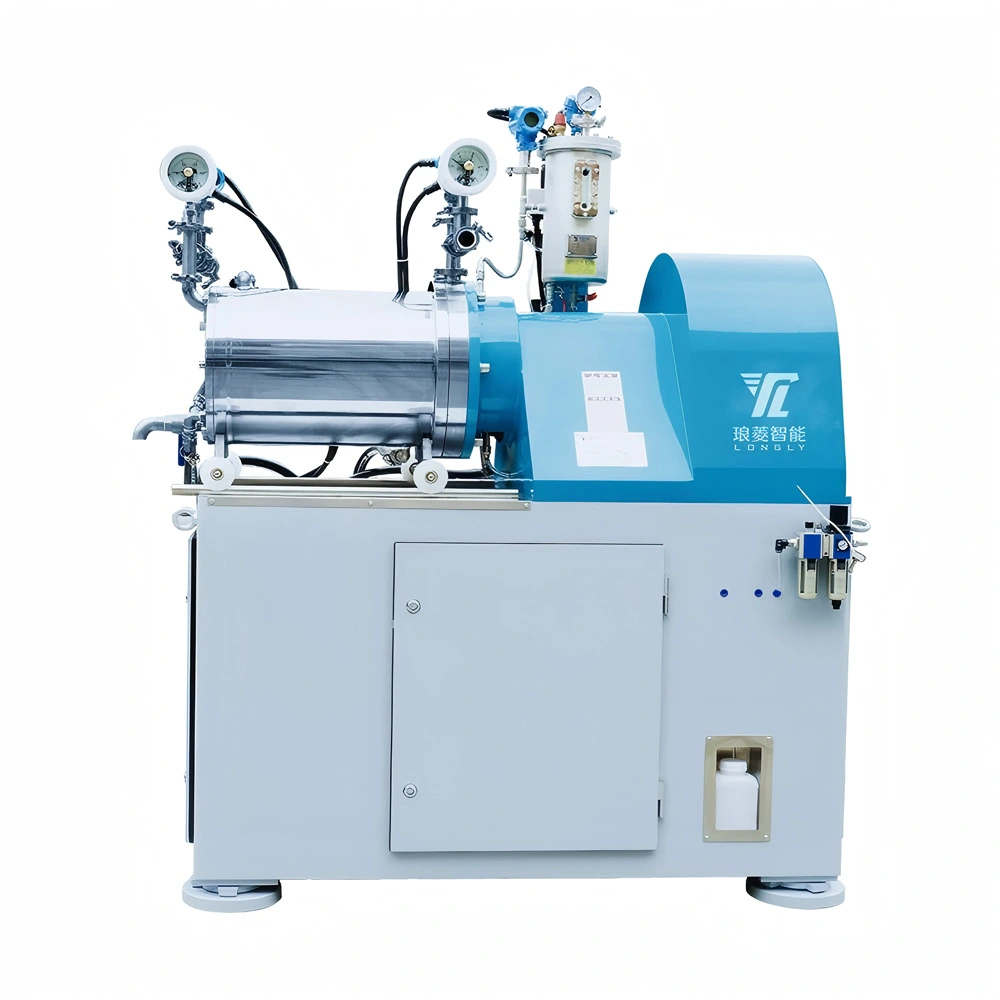

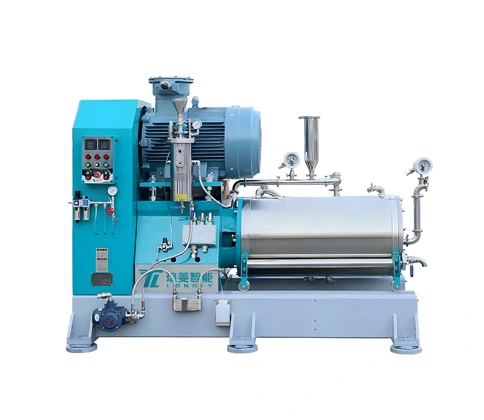

Delicately developed for high-viscosity materials with the upgraded version pin-type grinding structure and highly equipped power system for sufficient power, high speed, high filling rate of zirconium beads, stronger impact, and shearing effect.

It is especially suitable for materials with high viscosity, heat sensitivity, and difficulty in dispersion.

The patented dynamic screen system has a large flow without clogging.

It has outstanding superiorities in color paste, ink, pigment, dye, furniture paint, and automobile paint.

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский português

português Deutsch

Deutsch