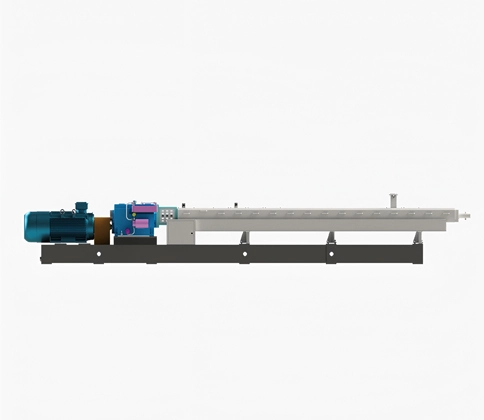

The material moves at high speed in the gap between the multi-layer rotor and the stator, forming strong hydraulic shear and turbulent flow, dispersing the material, and simultaneously generating comprehensive forces such as centrifugal extrusion, grinding, and collision, and finally fully mixing,stirring and refining the material to meet the ideal requirements.

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский português

português Deutsch

Deutsch