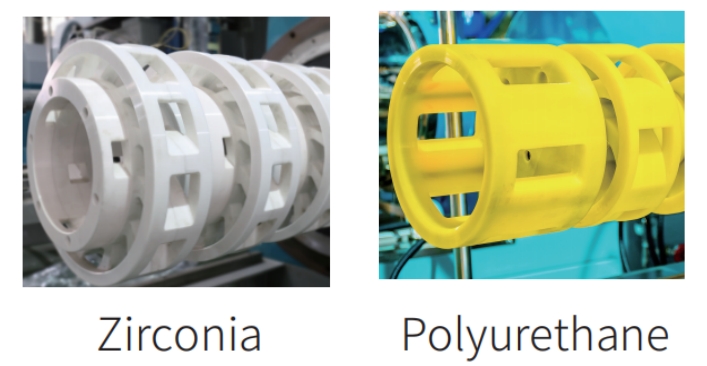

The conveying pump will pump the pre-diluted and stirred liquid-solid mixed raw materials into the grinding chamber. And the main shaft drives the dispersing turbo to rotate at a high speed and stirs the grinding media (glass beads, ceramic beads, zirconia beads, alumina beads, etc.) in the grinding chamber. It generates swirling flow and radial and axial movement to grind and disperse the material. So the material can reach the set fineness. At the same time, the working pressure and working temperature are automatically controlled by the electric contact pressure gauge and electric contact temperature gauge to ensure the safe operation of the whole machine. During this period, the product and the grinding media are separated through a dynamic discharge gap.

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский português

português Deutsch

Deutsch

.jpg)