Inquiry

English

English

+86 139 2572 1528

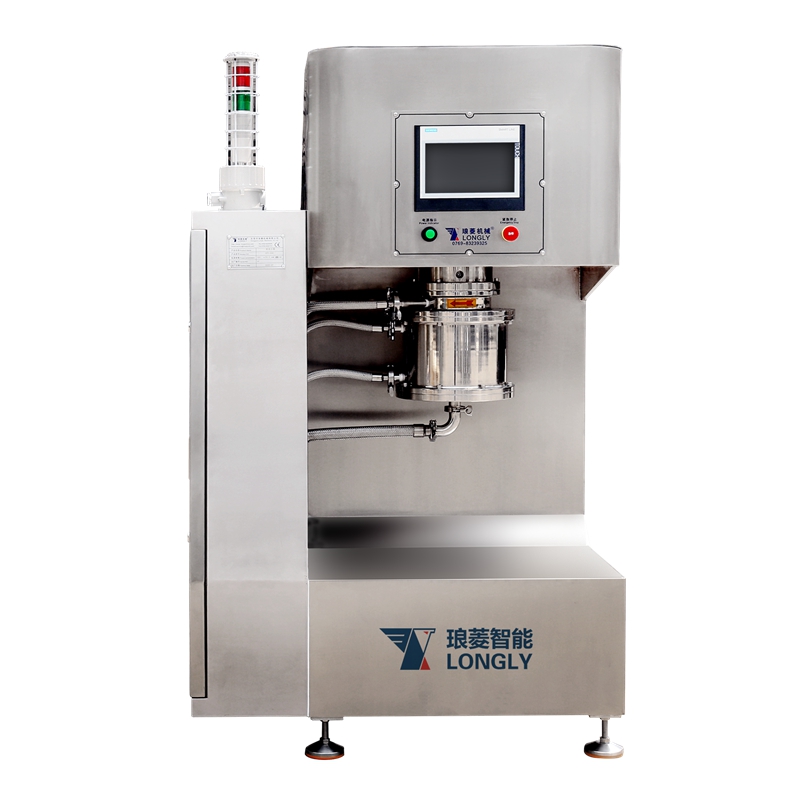

Grinding & Dispersing Systems, Designed for Your Profits

-

Products & Solutions

-

Industries & Application

-

Services & Support

-

string(2) "23"

string(2) "24"

string(2) "25"

string(2) "26"

string(2) "27"

string(2) "28"

string(2) "29"

-

- EPC Projects

中文

中文 Pусский

Pусский عربى

عربى Español

Español Tiếng Việt

Tiếng Việt